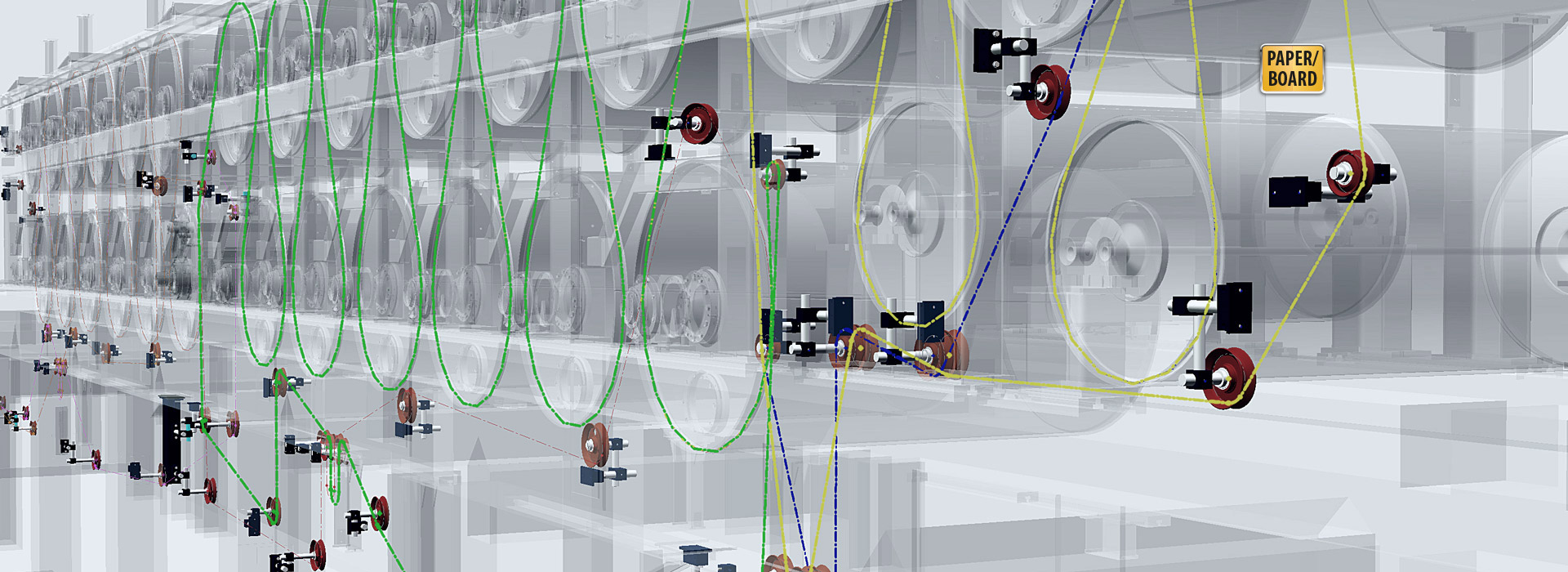

Tail Threading System Paper Machine

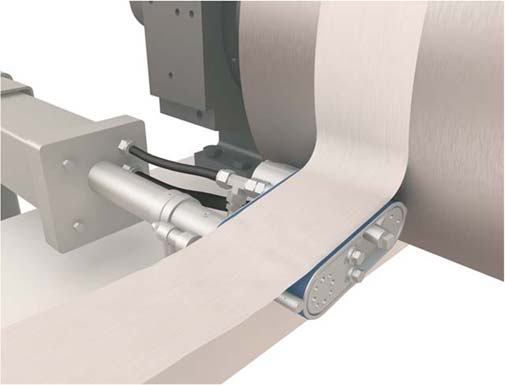

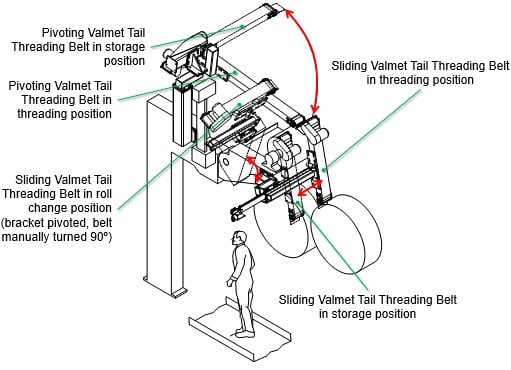

The benefits of ropeless tail threading with runtech systems technology are numerous.

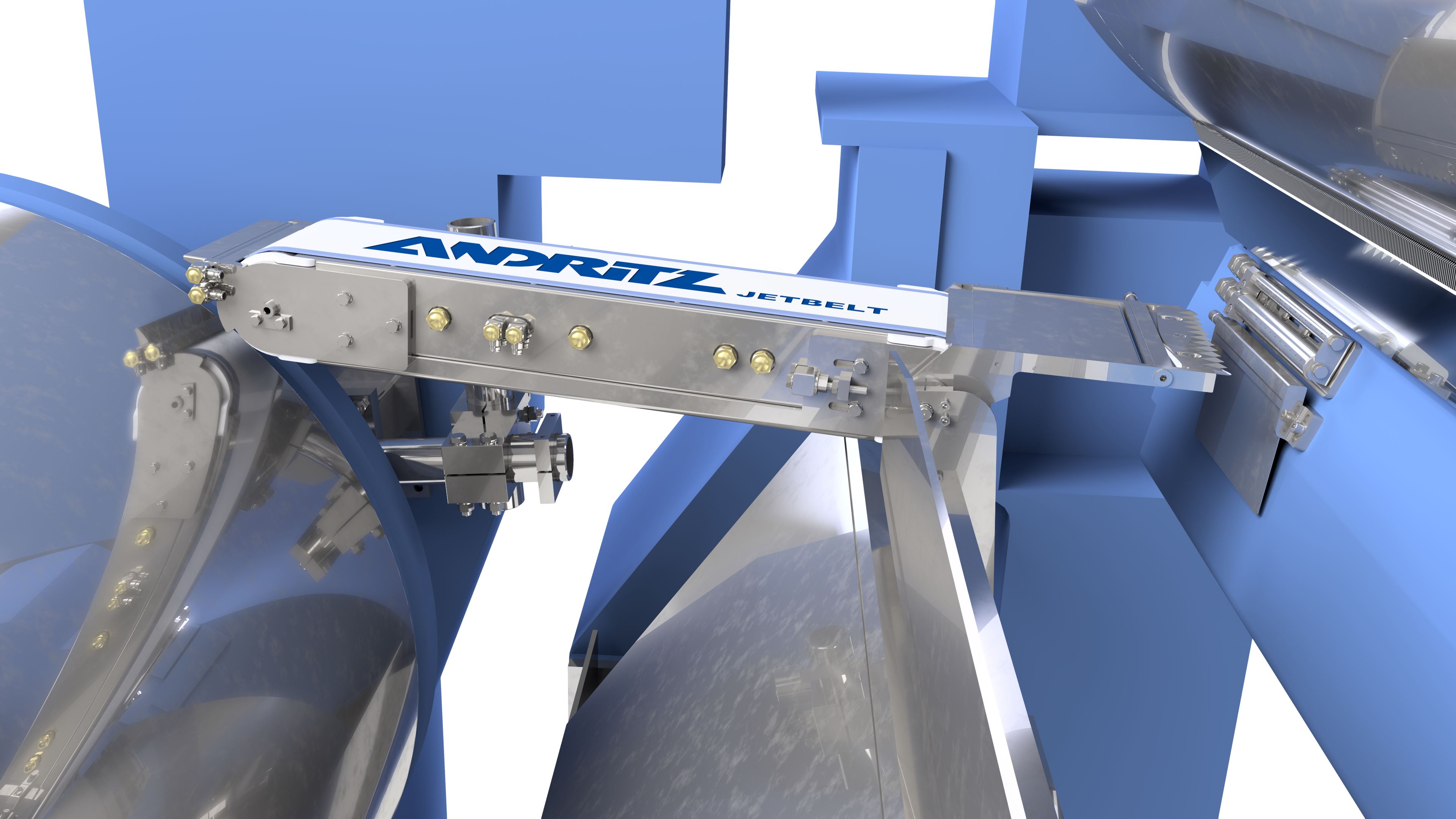

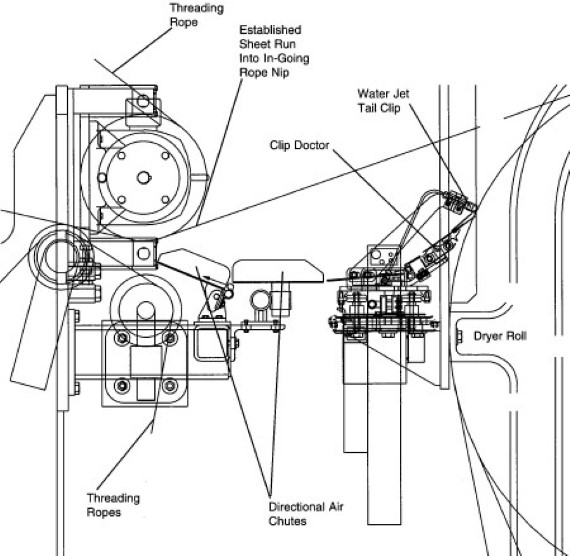

Tail threading system paper machine. A papermaking machine uses a low pressure water jet mounted on a pneumatic actuator for movement at least as fast in the cross machine direction as the paper web moves in the machine direction for a distance of 2 to 12 inches. Recognize the safety hazards and safety guidelines associated with tail threading equipment. Toscotec engineers and supplies a complete line of tail threading devices for all paper machine sections regardless of the paper grade and machine configuration. However many mills still carry out tail threading with a conventional carrier rope system that presents serious hazards for the staff.

It is a further feature. United states patent 5762759. Tail threading system for a papermaking machine. Describe the sheet threading process on a paper or board machine.

Tail threading concept and equipment. Today operator safety is a must and one of the top priorities in every paper and board mill. Whether you need improvements in paper board or tissue machines valmet has an advanced tail threading solution that clearly enhances your production efficiency. The jet rapidly cuts a tail with a blunt edge of 2 to 12 inches wide from the web.

A reliable tail threading process decreases tail threading times minimizes waste and improves safety. The actuator is mounted on a screw or belt driven carriage to traverse the web and. These threading devices are the perfect tool for new machines or to improve the efficiency and safety of an existing line. Runnability orientated runpro offers web stabilizing machine geometry modifications and ropeless tail threading solutions to eliminate runnability problems and to ensure fluent paper making process.

This means an investment in your process is an investment that pays for itself. A papermaking machine uses a low pressure water jet mounted on a pneumatic actuator for movement at least as fast in the cross machine direction as the paper web moves in the machine direction for a distance of 2 to 12 inches.