Stress Corrosion Cracking Stainless Steel Caustic

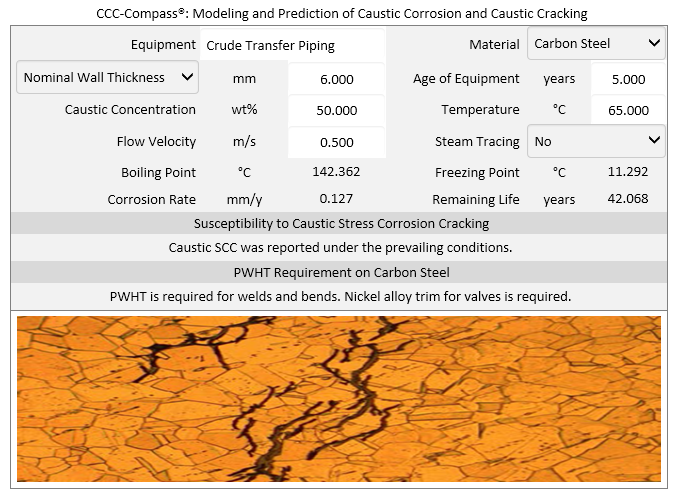

Corrosion of stainless steel by hot caustic research using solutions of chemically pure caustic sodium hydroxide naoh led to the development of a diagram that attempts to delineate the param eters of concentration and tem perature governing stress corrosion cracking scc of type.

Stress corrosion cracking stainless steel caustic. The impact of scc on a material usually falls between dry cracking and the fatigue threshold of that material. Caustic stress corrosion cracking no. Design or manufacturing details where chlorides can accumulate e g. Sodium hydroxide caustic soda is a strong base.

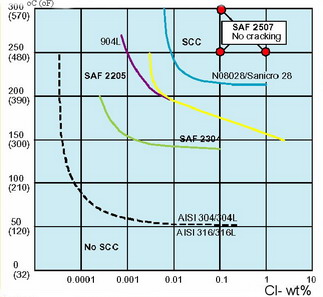

Selection of stainless steels for handling sodium hydroxide naoh introduction. Operation causes stress cycles. 13 corrosion in caustic solutions. Stress corrosion cracking scc is the cracking induced from the combined influence of tensile stress and a corrosive environment.

Chloride caustic and polythionic acid stress corrosion cracking introduction to electroplating interview with jane debbrecht corrosion in the news. Corrosion by caustic sodium or potassium hydroxide at all concentrations is easily handled. Prevalent afflictions in the industry and one of many environmental cracking mechanisms that typically occur in carbon steel equipment but it can also afflict low alloy and austenitic stainless steel equipment. An overview of chloride caustic and polythionic acid stress corrosion cracking is present.

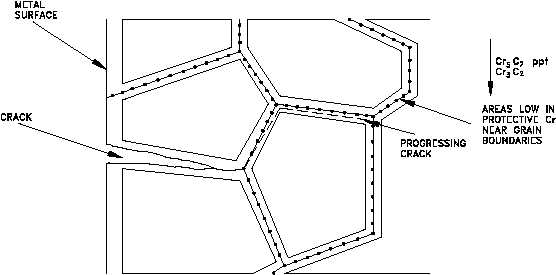

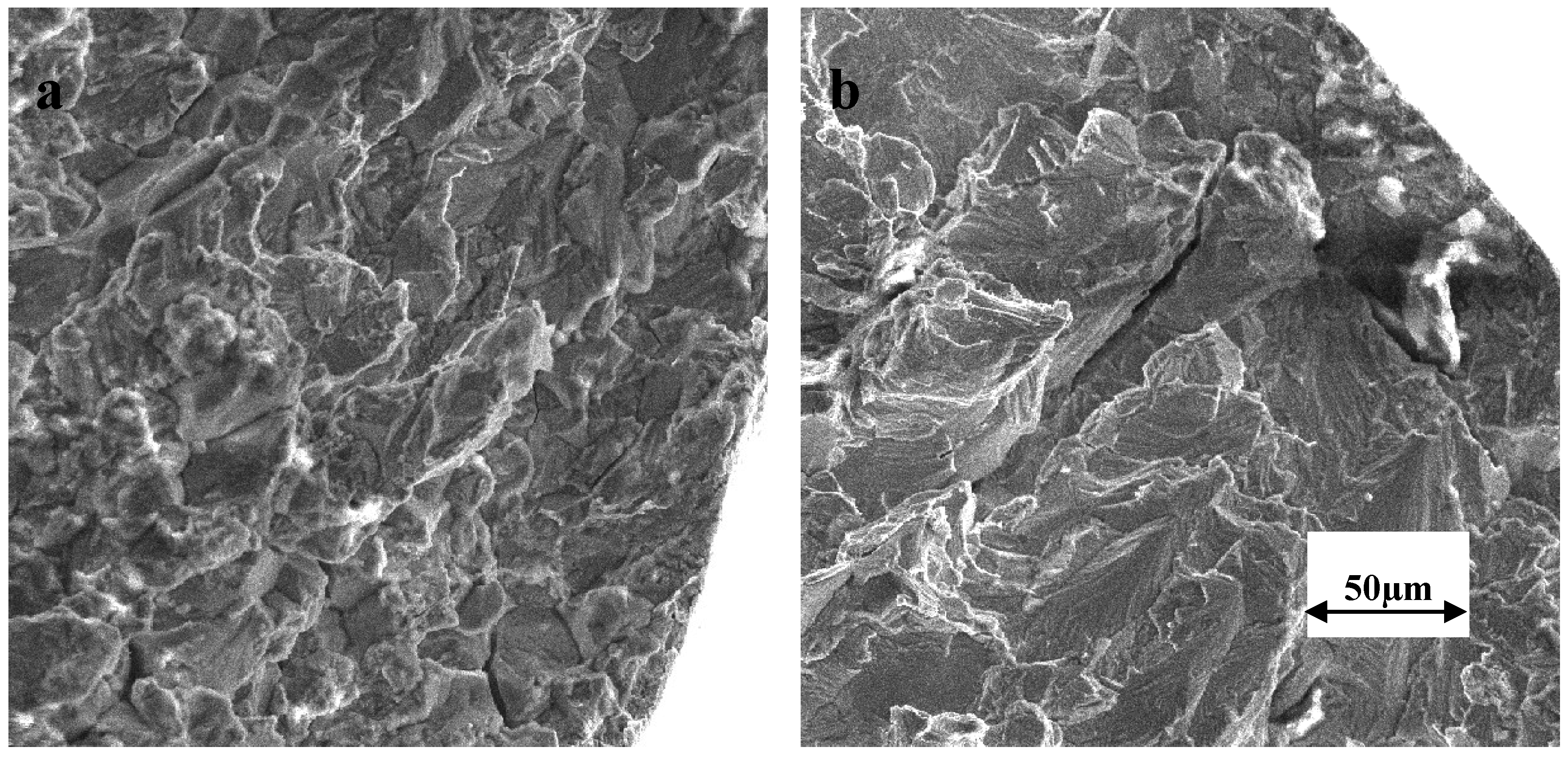

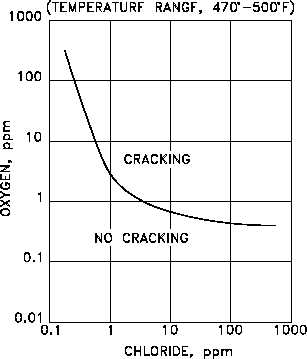

Chloride stress corrosion is a type of intergranular corrosion and occurs in austenitic stainless steel under tensile stress in the presence of oxygen chloride ions and high temperature. Stress corrosion cracking scc stress corrosion cracking. It is recommended that susceptibility to clscc is assessed by extending the api 581 approach. It is used in metal degreasing and cleaning processes in a wide range of industry applications.

September 21 2020 roundup. Caustic stress corrosion cracking is a form of degradation that is caused when a component operates in a.

.gif)