Steel Wire Strength Calculator

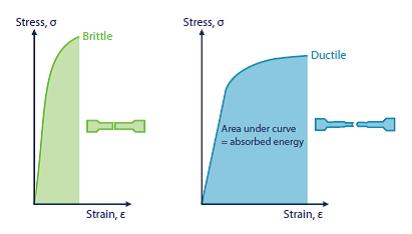

For straightened and cut lengths the minimum tensile strength will be be approximately 90 of the values listed in the table.

Steel wire strength calculator. Circular metal wire mesh inside a pipe. The rope selection calculator serves as an initial guide to selecting a rope. The following formula can be used to estimate the collapse strength of continuous slot screen. The calculator is implemented so you can bookmark and email results.

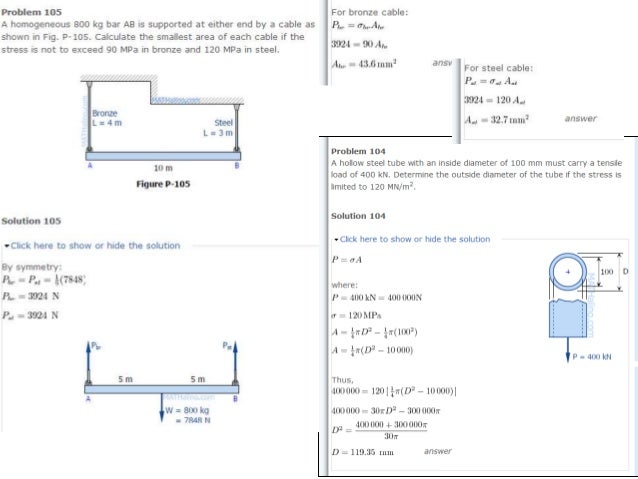

I moment of inertia in 4. Based on the input of desired strength fibre and construction the calculator returns the theoretical weight diameter and installation modulus. Spring temper values are in accordance with astm a 313. 6 strand x 19 wire 6x19 minimum breaking strength safe loads and weight engineering toolbox resources tools and basic information for engineering and design of technical applications.

489 6 lbs ft3 2833 lbs in3. The multiplier field can be used to factor in return path multiplier 2 or r rf r dc resistance factor from skin depth calculator. This data is for spooled wire. This calculator estimates the amount of elastic stretch experienced by 7x7 stranded wire rope constructed from 302 304 stainless steel that has been proof loaded to 60 of its breaking strength to remove constructional stretch.

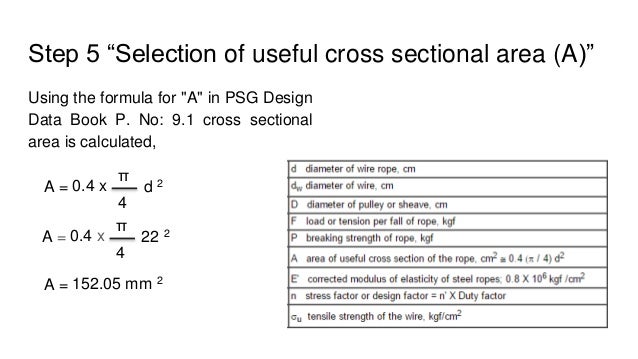

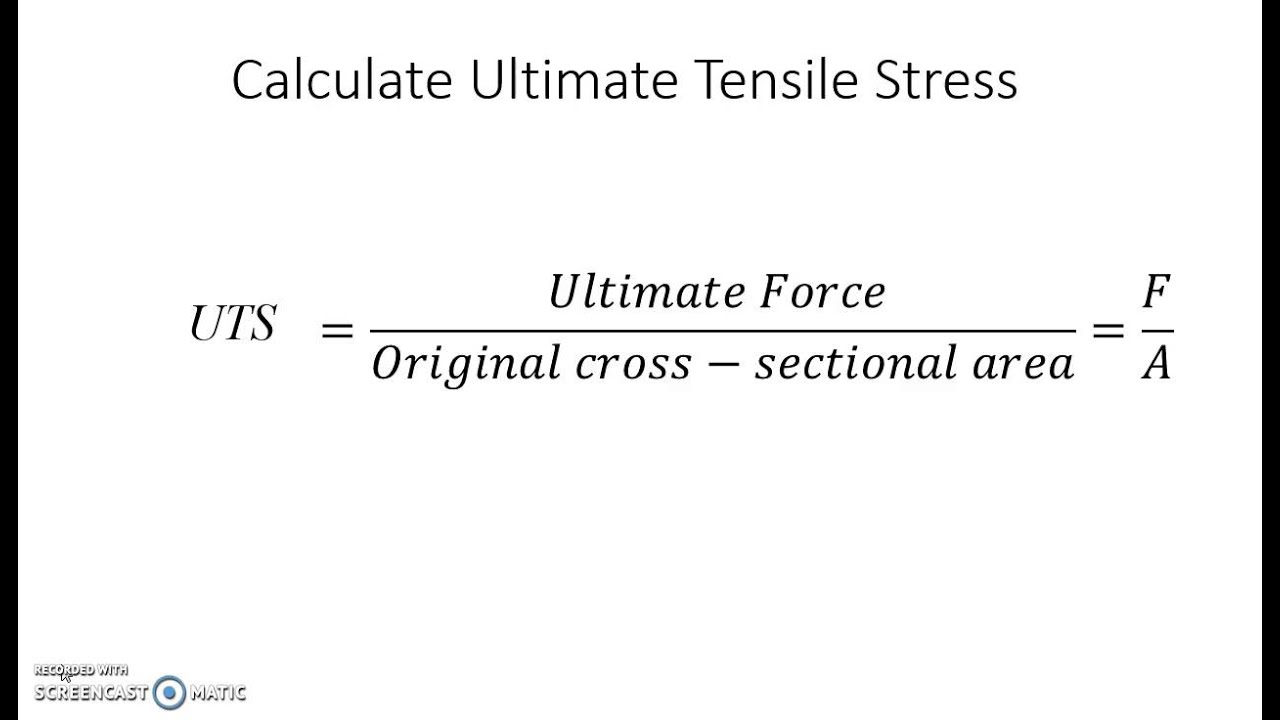

Collapse strength of continuous slot screen is dependent on diameter of the screen size shape and material type of wire used in its manufacture and the slot size. No consideration is taken to the eventual reduction in tensile strength during the stranding process. Resistivity of a material is the resistance from face to opposite face of a 1m cube of a material. 60155 this is a calculated value based on the sum of the total steel area multiplied with the tensile strength of each wire.

The values calculated are an approximation only. Tensile strength of stainless steel wire. Resistivity varies with different metals a few common conductors are listed below. Calculators and review the brinell hardness test uses a hardened steel ball indenter that is pushed into the material under a specified force.