Steel Plate Lamination Checks

4 2 the term lamination factor s pertains strictly to the determination of the proportion of material as defined by precise sampling and.

Steel plate lamination checks. Edge lamination defect can reduce the integrity of connections made to the edge of a plate. I have a problem in channel. The specifications for general requirements for steel plates for pressure vessel are given in asme ii part a sa 20 sa 20m. If the lamination direction is perpendicular to the stress direction in other words the lamination is reducing the load carrying cross section then it is a problem and needs to be sized and most probably removed.

1 can ut test in all condition read this defects. 2 can the plate be used for bottom plate of corrosive tank of 200 m3 although the tank is having rubber lining and acid proof brick lining. Laminations are caused by a variety of things including the presence of folds layers foreign materials and trapped gases during the rolling of steel. Which standard followed for this problem.

Available standards ut for lamination in steel plate. While checking a welder test piece it was found that a 12 mm steel plate is having clear lamination. During this process carbon steel may pass through the rollers many times to achieve the desired thickness. A carbon steel plate is produced by the process of hot or cold rolling a thick slab.

In reply to rick lopez at 22 48 oct 09 2012 opening. Each pass results in an increase in the area of the plate and decreases in thickness. Lamination plate made of hardened stainless steel. Its possible to lamination occur in channel.

Extremesteel combines high scratch resistance with long term stability necessary for the demanding card manufacturing environment. Check out the welding and the lamination. Carbon steel plate lamination defect reasons. Thnks regards pankaj 919997334540.

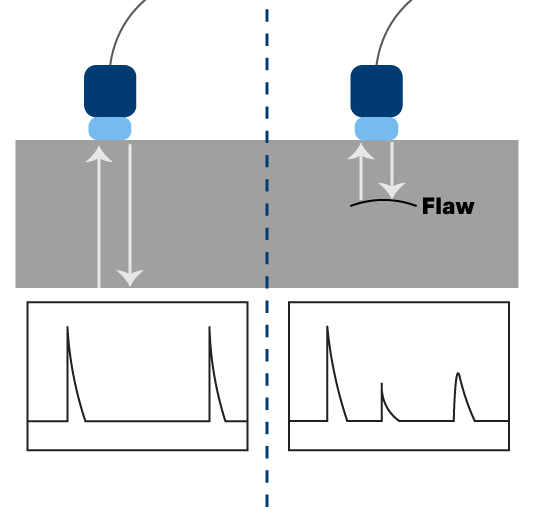

Describes ultrasound testing methods for rolled plate. Plate lamination defect acceptance criteria. 4 1 lamination factor s indicates the deficiency of effective steel volume which is due to the presence of oxides roughness insulating coatings and other conditions affecting the steel surface. A lamination is an imperfection or defect in a steel or other metal alloy material that can impair structural performance.

Describes the ultrasound testing method for thick steel plate. For laminations exceeding these limits the manufacturer shall either reject the plate or repair the plate by entirely removing the lamination. The maximum allowed lamination is 25 mm 1 in visible to the unaided eye on the edge. Dear sir i want to know there is any standard for lamination in ismc channel.

Describes the automatic ultrasound testing of strip and plate used for the production of welded steel tubes for detecting lamination.