Steel Pipe Piles Filled With Concrete

If driven with plates the pipes can then be filled with concrete to add strength to the pile.

Steel pipe piles filled with concrete. If a steel pipe pile is filled with concrete and adhesion between steel and concrete is sufficient the structure can be assessed as a composite structure. Drawings and general provisions of the contract including general and supplementary conditions and division 1 specification sections apply to this section. 2 unplugged open ended steel pipe pile. Usually the money spent on plates rebar and concrete would be better spent on a larger thicker pile.

In this case also after driving the hollow space inside the pipe is normally filled with concrete. In some cases pipe piles are filled with concrete to provide additional moment capacity or corrosion resistance. This is the conical shoe. The article discussed some of the benefits of filling hss columns with concrete including increased strength and a potential.

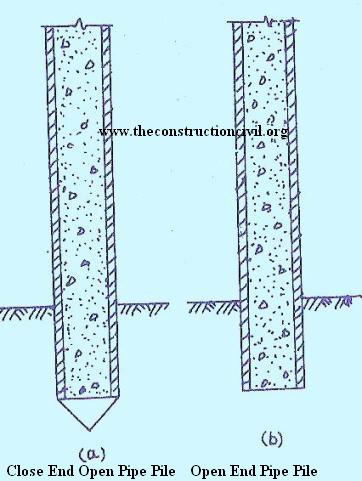

Composite concrete filled hss. If a concrete filled pipe pile is corroded most of the load carrying capacity of the pile would remain intact due to. In this type of pipe piles a conical element either made of steel or cast iron is attached to the open bottom by means of welding. Kim olson and benjamin kaan authored an enews article titled practical guidance for concrete filled hss columns in september 2015.

Pipe piles range in size from several inches to several feet in diameter and can be easily spliced to create piles hundreds of feet in length. In most cases pipe piles are filled with concrete. In case of closed end piles the driving end of each piling pipe is closed by welding a bottom steel conical steel or cast iron rock shoe to the pipe end. June 24 2014 31 62 16 1 concrete filled steel piles section 31 62 16 concrete filled steel piles part 1 general 1 01 related documents a.

After driving the steel pipe to required depth the steel pipe is filled with concrete of standard specification. Closed end pipe piles are constructed by covering the bottom of the pile with a steel plate or cast steel shoe. The montana department of transportation has found concrete filled steel tube cft piles connected at the top by a concrete pile cap to be a very cost effective support system for short and medium span bridges. Close end pipe piles.

If pipe piles were not filled with concrete then corrosion protection layer should be applied. By jason ericksen se technical consultant to the steel tube institute. If an empty pipe is required a jet of water or an auger can be used to remove the soil inside following driving.