Steel Pipe Corrosion Protection Methods

Stainless steel is resistant but certainly not immune to corrosion.

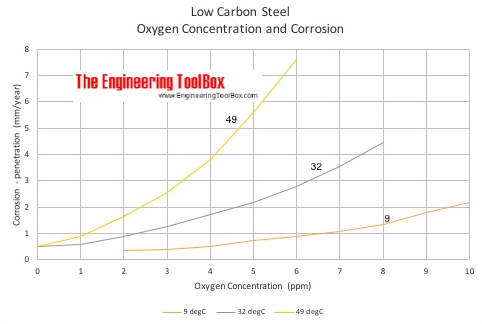

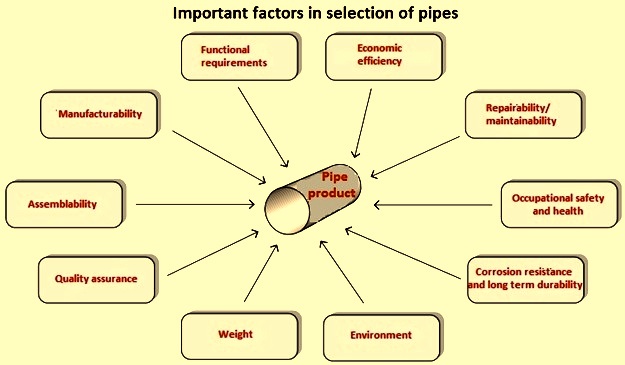

Steel pipe corrosion protection methods. In a previous article we examined the need for inspecting stainless steel pipes further including a discussion of conditions which encourage corrosion. Two forms of. Carbon steel pipe can be manufactured using several different techniques each of which produces a pipe with certain characteristics. Corrosion is a natural process which converts a refined metal to a more stable form such as its oxide hydroxide or sulfide.

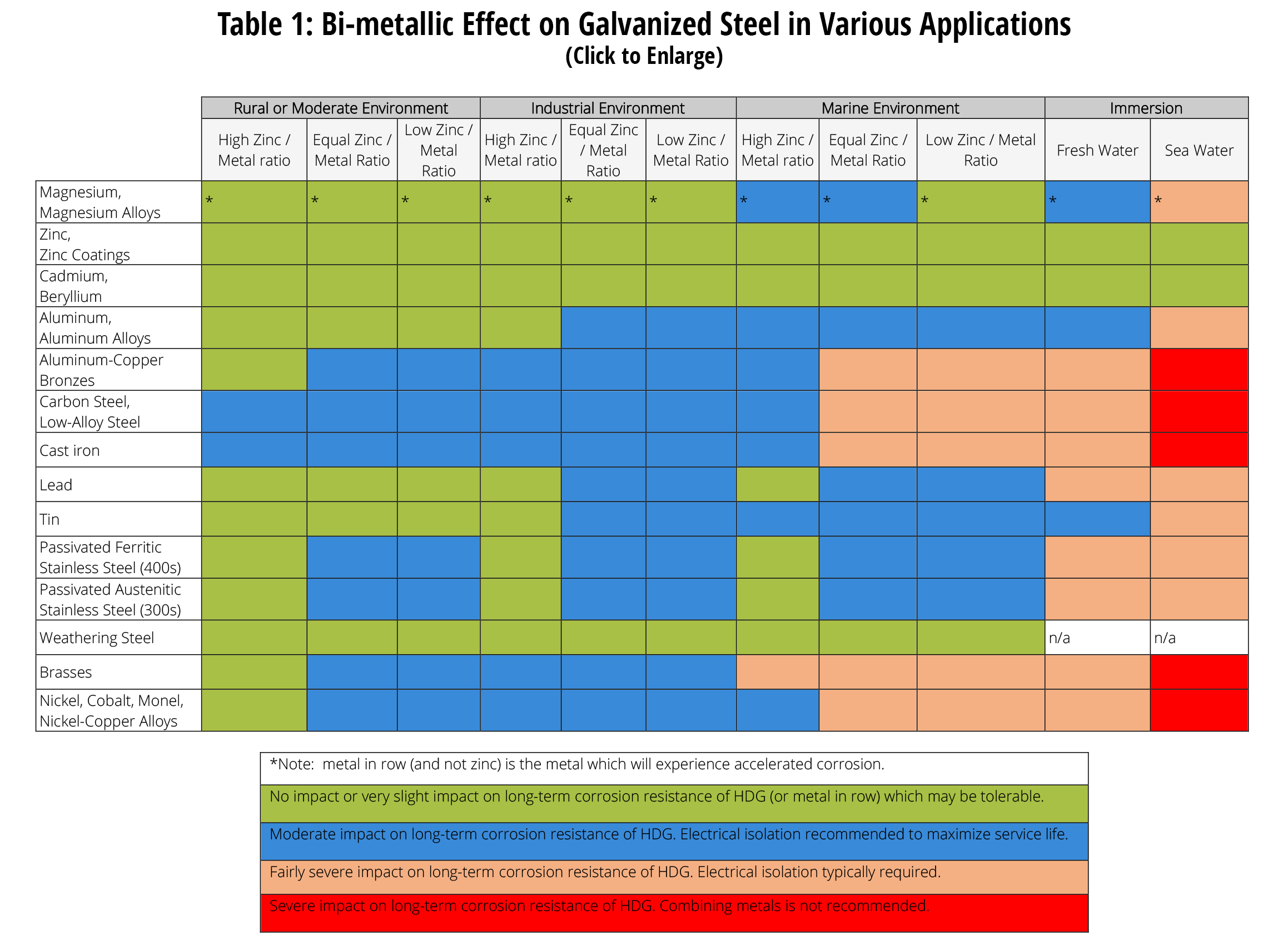

A simple method of protection connects the metal to be protected to a more easily corroded sacrificial metal to act as the anode the sacrificial metal then corrodes instead of the protected metal. Painting has an advantage when appearance and choice of color are important. Painting zinc coatings hot dip galvanizing and combinations of these. It is generally used when a pipeline is buried underground or in water.

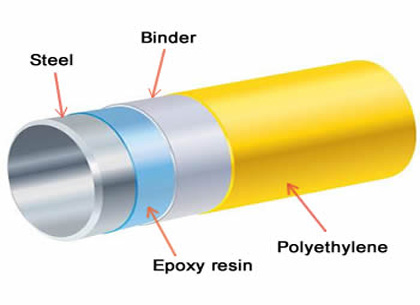

Coatings provide physical barriers that do not allow corrosive materials to come in. In the steel pipe world corrosion protection generally refers to keeping the steel pipes from being converted to iron oxide rust. Internal corrosion control should be carried out for pipeline systems carrying corrosive hydrocarbons. Steel pipe corrosion protection methods.

When executed on a new pipeline cathodic protection can prevent corrosion from the start. Specifically in steel pipelines there are three main types. There are many methods to reduce corrosion in all types of structures. This technical bulletin will consider four methods of protecting carbon steel pipe supports components from corrosion.

Cathodic protection cp is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. Coatings corrosion inhibitors and cathodic protection. The performance of a coating is significantly influenced by its ability to adhere properly to the substrate material. Surface preparation is the essential first stage treatment of a steel substrate before the application of any coating and is generally accepted as being the most important factor affecting the total success of a corrosion protection system.

Deep anode shallow distributed anode bed and linear anodecathodic protection. This article reviews 3 steel pipe corrosion protection methods utilizing cathodic protection. For submarine pipelines the internal corrosion control methods include the use of corrosion inhibitors plus corrosion allowances internal coatings and corrosion resistant pipes or linings to keep the transport medium dry. When corrosion does occur in stainless steel the corrosion often manifests in a very localized manner rather than uniform or general corrosion.

Cathodic protection cp is a method to control corrosion by using a direct electrical current which neutralizes external corrosion typically associated with a metal pipe.