Steel Lamination Test

Answered september 4 2018.

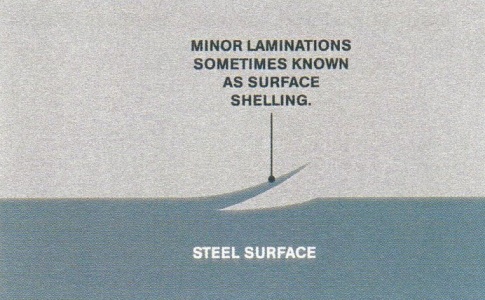

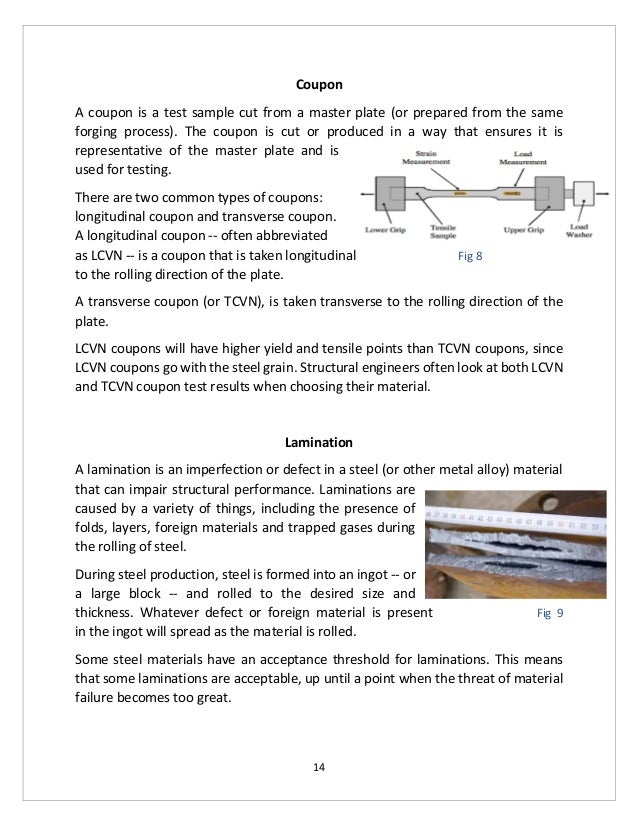

Steel lamination test. 4 1 lamination factor s indicates the deficiency of effective steel volume which is due to the presence of oxides roughness insulating coatings and other conditions affecting the steel surface. Small laminations may also be welded over and blended polished back into the base metal. The other 4 parts of the test is pretty much common scence. Basic math decimals fractions addition subtracting and division pretty basic but refreshing your skills a few days before test wouldn t hurt.

Moreover these testing procedure are also in compliance with international standard test method of electrical. Because inclusions and laminations are not always found throughout an entire bar plate or other form we should attempt to work through the issue. Took assessment test 8 29 18 for us steel gary indiana. 4 2 the term lamination factor s pertains strictly to the determination of the proportion of material as defined by precise sampling and.

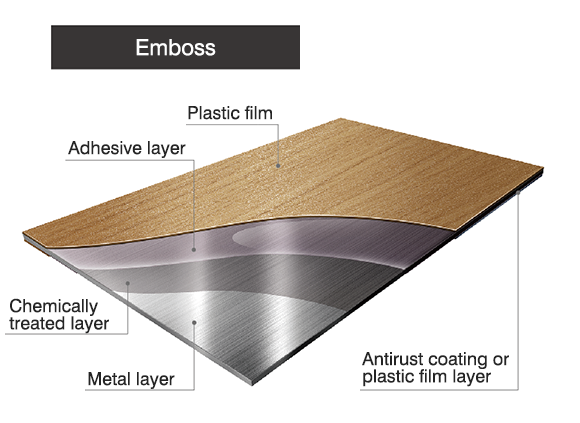

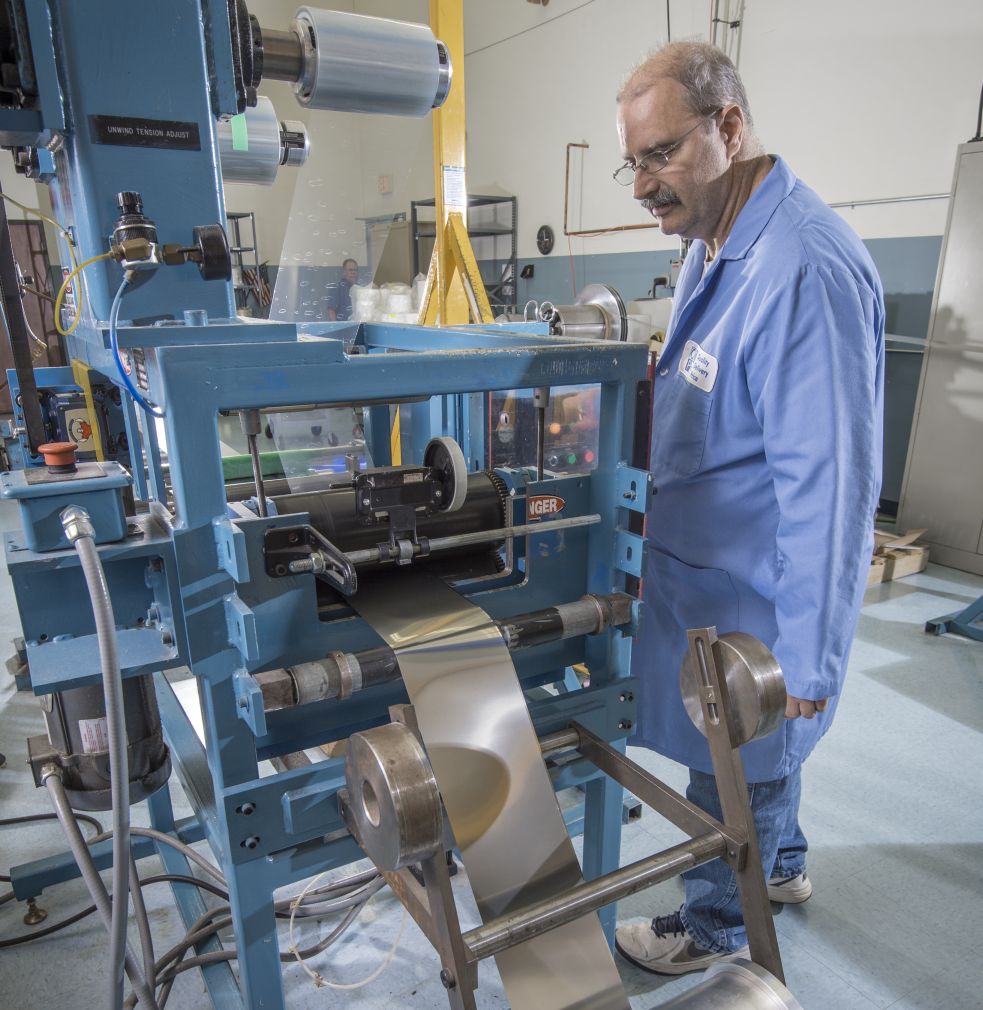

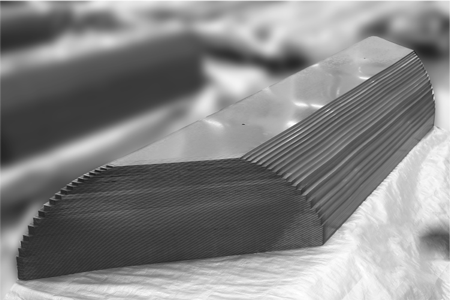

The most common concern for field welding with respect to line pipe are laminations. 12 5 mm and over in thickness. For some projects to produce test samples and smaller batches of laminations in the optimal way we use also the single notching technology and laser cutting. Electrical steel is usually manufactured in cold rolled strips less than 2 mm thick.

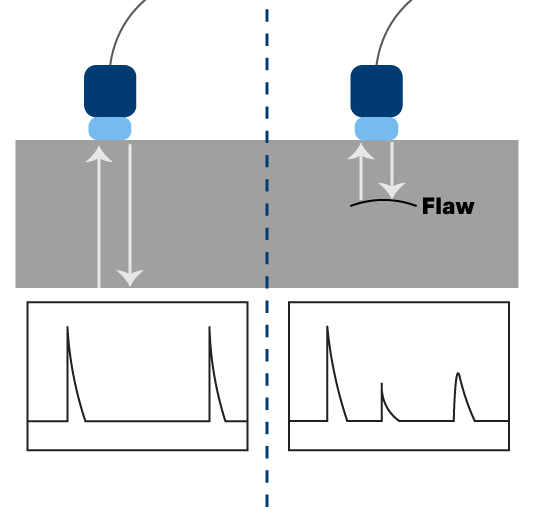

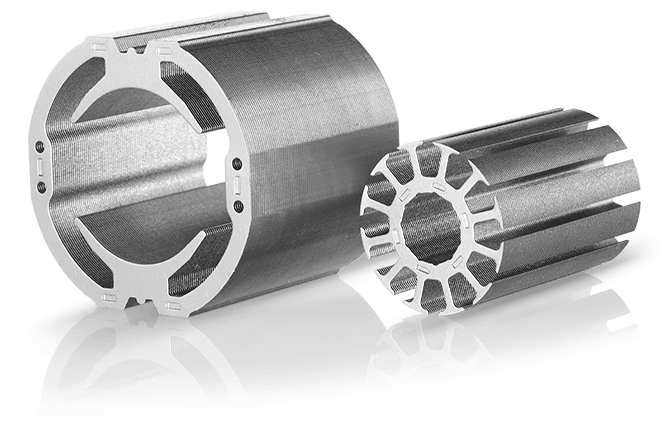

Lamination testing lamination testing 1 lamination testing july 2004 background there is a concern about the presence of what is loosely defined as laminations in tubular products and they have arisen out of a variety of installation and service conditions. 1 1 this specification 2 covers the procedure and acceptance standards for straight beam pulse echo ultrasonic examination of rolled fully killed carbon and alloy steel plates 1 2 in. Lamination defect of a significant area will impair the structural performance of welded objects to the plate surface and may result in a local buckling failure. Lamination specialties is a full service supplier of electrical steel since 1956 specializing in grain oriented go non grain oriented ngo and cold rolled motor lamination crml.

We also offer thin gauge low loss grades for special applications with technical support to better understand customer needs and recommend most cost effective. We are able to offer a superior quality steel strips testing machine which is used for testing of electrical steel sheet of all grade and gauges the testing procedure of this instrument is simple and user friendly. Small hysteresis area resulting in low power loss per cycle low core loss and high permeability. Electrical steel lamination steel silicon electrical steel silicon steel relay steel transformer steel is an iron alloy tailored to produce specific magnetic properties.

The carbon steel blister in photograph would be an exception to that comment. We produce laminations made of electrical steel for orders of large batches with rapid stamping in which we use the latest technologies and modern trends in this industry. Lamination defect in steel plates is highly undesirable for dynamically loaded elements of steel structure such as high pressure temperature storage tanks vessels.