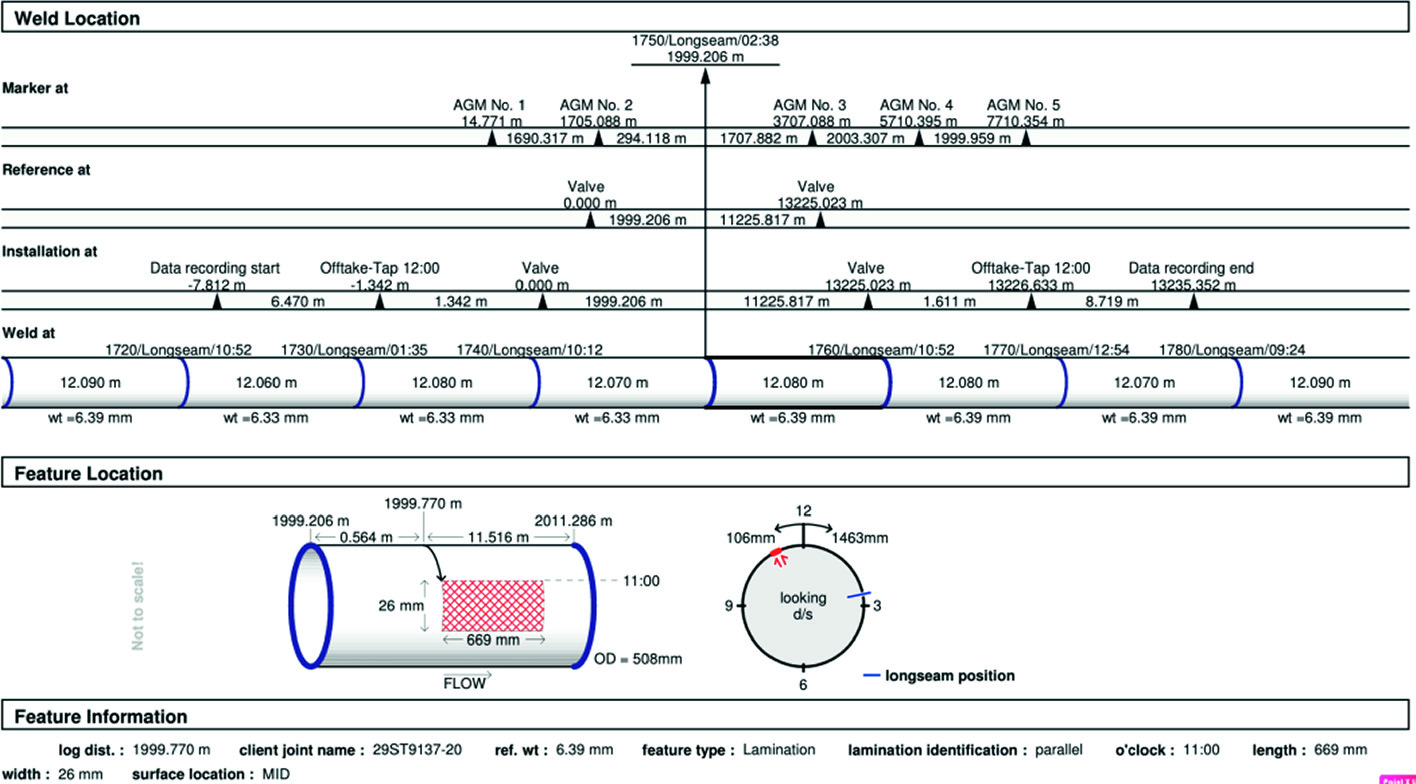

Steel Lamination Defects

Lamination defect in steel plates is highly undesirable for dynamically loaded elements of steel structure such as high pressure temperature storage tanks vessels.

Steel lamination defects. Indeed they were latent at the time that the steel was manufactured. Pressure vessel lamination blistering complex parameter. These defects were latent at the time that the boiler was manufactured. Delamination is a mode of failure where a material fractures into layers.

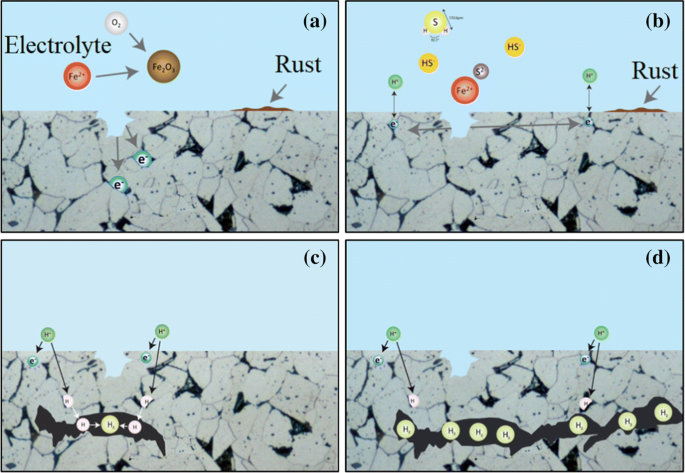

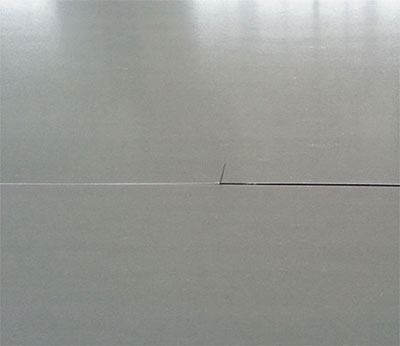

Also surface coatings such as paints and films can delaminate from the. Because the end of the steel had received a light weld coating the laminations were not discoverable by dye checking as there was no crack at the surface. Industrial facility with structural defects evolving with time. When we encounter longitudinal linear defects in our steel products using a micro to characterize the nature of the decarburization and presence or absence of sub scale or ferrite fingers are important evidence as to when where and how in the process the defect originated.

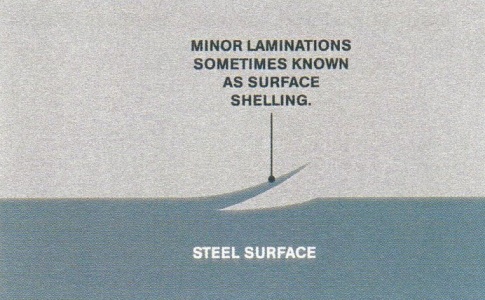

Most people hear the words inclusion or lamination and think defect but one should not fear these words and automatically think of defect or rejection. Processing can create layers in materials such as steel formed by rolling and plastics and metals from 3d printing which can fail from layer separation. Lamination defect of a significant area will impair the structural performance of welded objects to the plate surface and may result in a local buckling failure. If the lamination direction is perpendicular to the stress direction in other words the lamination is reducing the load carrying cross section then it is a problem and needs to be sized and most probably removed.

A variety of materials including laminate composites and concrete can fail by delamination. Stresses are concentrated at notches which occur at sudden changes in geometry. Laminations these are. Lamination defect of a significant area will impair the structural performance of welded objects to the plate surface and may result in a local buckling failure.

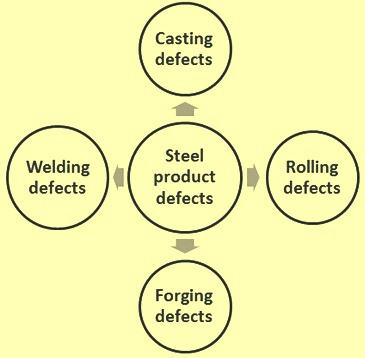

Another issue is when the material with the lamination is in compression when the lamination lies parallel to the stress direction. This approach allows us to define the main trends in defect development process and to make a decision about what kind of inspec tion should be performed while facility is under operation or intermittently stopped. Inclusions and laminations naturally exist in all metal and alloy products. Metallurgical processes and defects in steel products.

Defects in steel products are defined as deviations in appearance shape dimension macro structure micro structure and or chemical properties when compared with the specifications given in the technical standards or any other normative documents in force. Lamination defect in steel plates is highly undesirable for dynamically loaded elements of steel structure such as high pressure temperature storage tanks vessels. Very high concentrations of stress can develop at sharp notches.

.jpg)