Steel Lamination Defect Causes

Defects in continuous cast steel products.

Steel lamination defect causes. Lamination defect in steel plates is highly undesirable for dynamically loaded elements of steel structure such as high pressure temperature storage tanks vessels. Indeed they were latent at the time that the steel was manufactured. But the age old problems of layflat and air bubbles will always cause worry unless you and your supplier use three basic measurements. Only in severe circumstances are they cause for rejection and there are remelting processes that can significantly improve the cleanliness of the metal and reduce inclusions and laminations.

Another issue is when the material with the lamination is in compression when the lamination lies parallel to the stress direction. If the lamination direction is perpendicular to the stress direction in other words the lamination is reducing the load carrying cross section then it is a problem and needs to be sized and most probably removed. Delamination is a mode of failure where a material fractures into layers. It s hard to find a paper film or foil product that isn t a laminate whether the layers are from adding coatings or combining two or more.

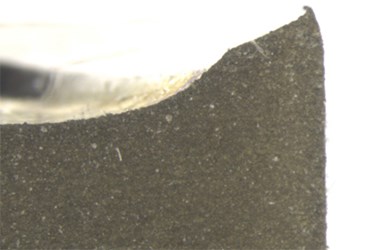

The laminated plate was determined to be defective for use as a furnace tube. That s why it s vital that all steel products are to the greatest extent possible defect free. Processing can create layers in materials such as steel formed by rolling and plastics and metals from 3d printing which can fail from layer separation. Because the end of the steel had received a light weld coating the.

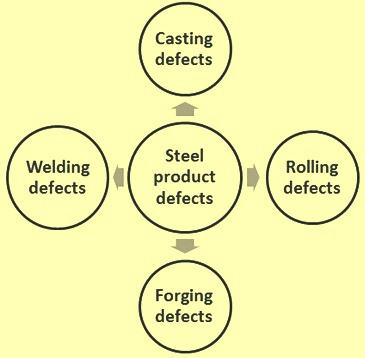

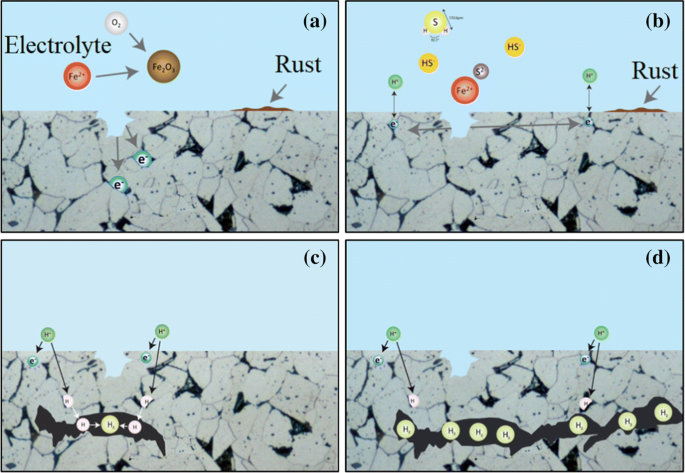

A variety of materials including laminate composites and concrete can fail by delamination. Defects of the continuous cast steel products are formed due to several factors which include material related factors casting speeds and temperatures mould oscillation casting powder segregation coefficient of solute elements phase transformation and mechanical and thermal stresses. As a key element in transportation construction appliances and many types of infrastructure we all rely on steel s strength and security under pressure. Lamination has become a regular part of the converting process.

Obviously identifying the root cause is critical. The world runs on steel. Lamination defect of a significant area will impair the structural performance of welded objects to the plate surface and may result in a local buckling failure. This defect was the primary cause of the boiler failure.

When we encounter longitudinal linear defects in our steel products using a micro to characterize the nature of the decarburization and presence or absence of sub scale or ferrite fingers are important evidence as to when where and how in the process the defect originated.

.jpg)