Steel Grit Blasting Rates

This normal for steel grit makes them perfect for air ship and aviation applications.

Steel grit blasting rates. Under this service we remove oil and grease before blast cleaning. In view of their precise nature steel grit can likewise be utilized viably to make a flawlessly carved surface on metal in anticipation of the attachment of paint polish elastic and different sorts of covering. Due to increase in surface area the blasting is done. Steel grit blast media is ideal for aggressive cleaning applications.

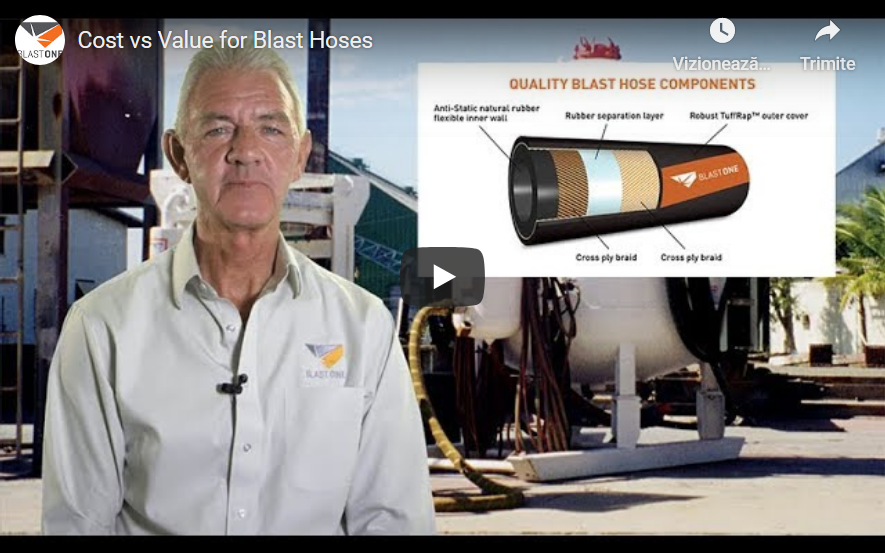

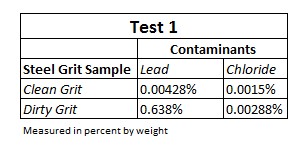

Steel grit have a high inflexibility and don t break effectively. Tip 10 estimating production rates blast cleaning. Abrasive expenses are not simply confined to the price of the abrasive. Steel grit and shot have one of the lowest breakdown rates of all blast media and can therefore be recycled and reused.

Grit blasting increases the surface area by producing a surface covered with small peaks and troughs. Steel grit and shot are generally available with diameters of 0 007 0 078 in. Steel grit will quickly strip many types of surface contaminants from steel and other foundry metals. With such a wide variety of coating types and rust conditions in existence at most plant sites how does a contractor estimate surface preparation production rates for bidding i e abrasive blast cleaning wet blast cleaning power tool cleaning etc.

Abrasive blasting more commonly known as sandblasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface roughen a smooth surface shape a surface or remove surface contaminants a pressurised fluid typically compressed air or a centrifugal wheel is used to propel the blasting material often called the media. Steel abrasive is a cost effective alternative to other abrasives due to its toughness and high recyclability. Machines can be built with multiple wheels for. Steel grit is softer than aluminum oxide grit and does not fracture as easily.

Steel shot grit. Steel grit is angular in shape whereas shot is round. The density is also high which helps impart more energy to the substrate being cleaned. Blast room and outdoor blast production rates blast specifications.

It can be used on a variety of surfaces to effectively remove contaminants texture a surface for proper adherence of a final coating or in peening hardening applications. The angular nature of steel grit produces an etched surface on metal for superior. Often when companies are estimating their blasting costs they consider each line item cost independent of the others and therefore seek to minimize each expense believing that is the best recipe for profitability. Being a prominent firm in this domain we are engaged in offering grit blasting metal coating service.