Standard Metal Stamping Tolerances

Bow tolerances are additive to the measured a b and c dimension.

Standard metal stamping tolerances. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the manufacturer s standard gauge which has no inherent tolerances. Tolerance which can be defined as the permissible limit or limits of variation in the manufacturing process is applied throughout the development of a metal stamping. The tolerances shown are well suited to the progressive stamping process and thus ensure quality and cost effective parts. Parts may be measured in either unrestrained or restrained conditions.

We would like to show you a description here but the site won t allow us. Recommended limits are applicable to parts measured in the unrestrained condition flatness tolerances for metal stamping. Tolerance class standard dimension range symbol description over 0 5 2 to 3 incl. Specifications for tolerance are often tweaked at each step of the design stage sometimes leading to an excessively tight tolerance which prohibits the execution and completion.

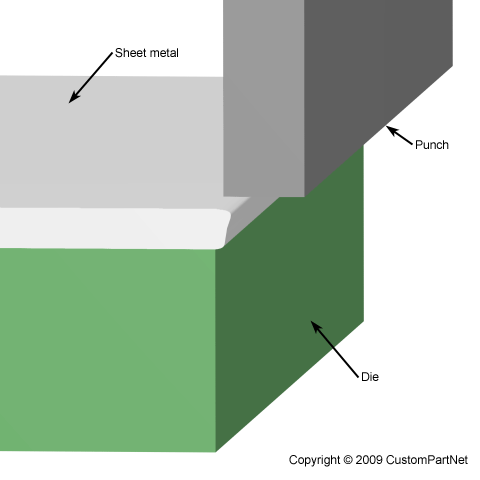

The normal result of the deep drawing process renders the closed end of the can and corner radius areas thicker than the side wall. Over 3 to 6 incl. Stamping design guidelines jonathan zhang 2 stamping design guideline stamping includes a variety of sheet metal forming manufacturing processes using a machine press or stamping press the processes including punching blanking embossing bending forming drawing flanging and coining. Of course exceptions apply.

This could be a single stage operation where every. Most common steel grades are offered in standard gage thicknesses and tolerances. Metal stamping is an economical way of producing quantities of parts that can have. Below are dimensions and tolerances typical of stamped metal components.

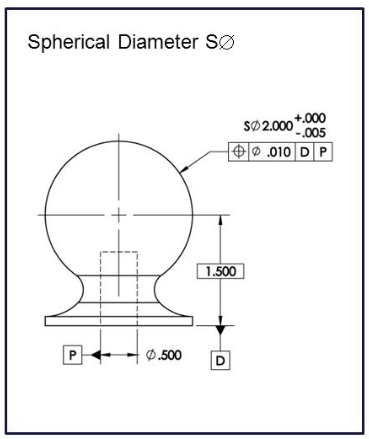

During the rolling process the rollers bow slightly which results in the sheets being thinner on the edges. Sheet metal guage tolerances. The basic a b and c dimensions and tolerances apply at the point of tangency of the radius. Temper tolerances angular tolerances on bends and station to station inaccuracies in.

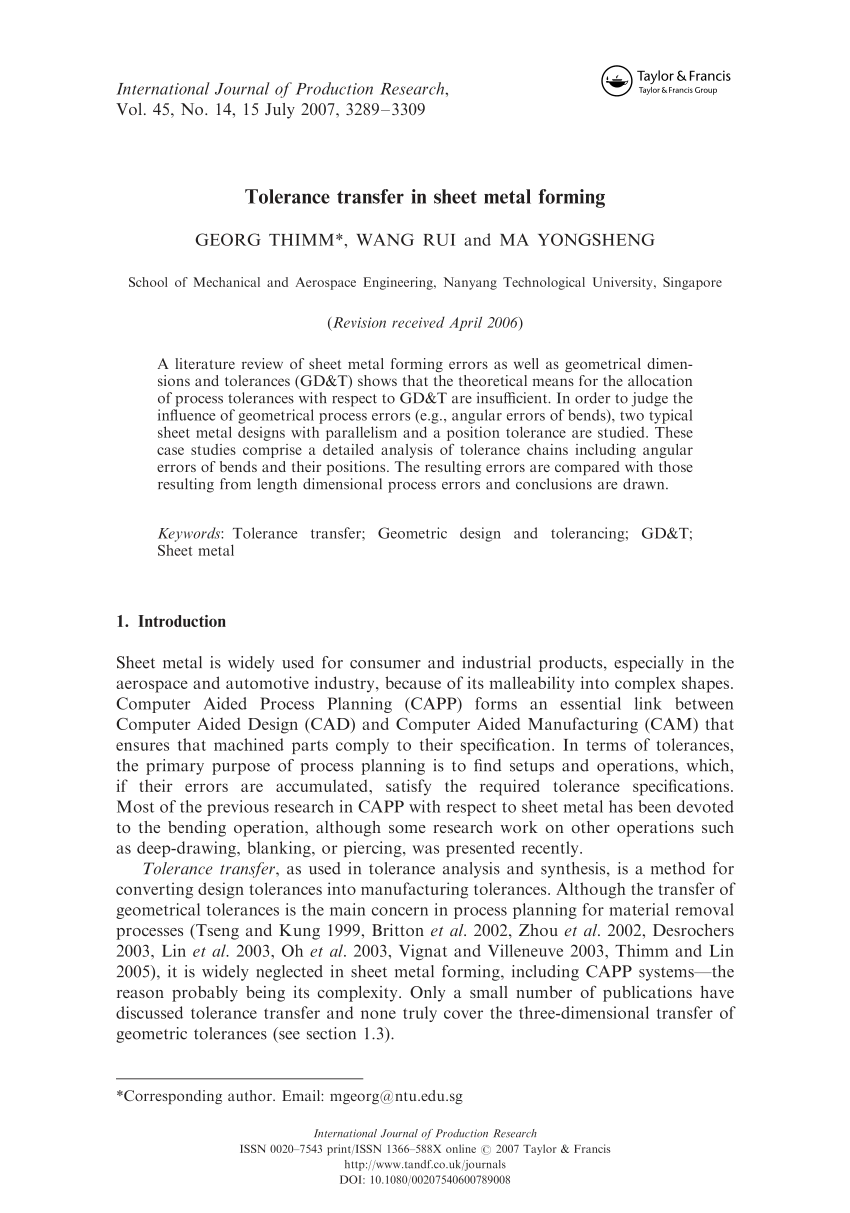

Flatness tolerance is the permissible distance between two parallel planes within which all irregularities of a given surface must lie.